A well designed, mechanically maintained industrial system may run for years without anyone ever needing to access the PLC code. While this is fantastic from a production standpoint, it may present some problems when someone finally has to access the PLC code.

- The PLC code may have been lost or misplaced

- The original vendor may no longer be able to service the equipment

- The PLC code is available but not documented

- Staff that was familiar with the equipment may have moved on.

We offer a several solutions to help resolve these situations. Our offerings will be developed specifically for your facilities needs.

Software Inventory

We can visit your site and inventory the software on any or all of the equipment at your site. This can include taking backups of PLC programs as well.

Once the inventory is produced we can work with your maintenance staff to identify any commercial software you may be missing such as RSLogix 5000 or TIA Portal and make purchase recommendations.

Targeted Software Training

All of the software gathered up in the Software Inventory is good to have on hand but having an understanding of how to use it on your plant floor is ideal. This customized training will work with your maintenance team to identify equipment that is currently difficult to work on. Then we will demonstrate the right techniques to connect to this system and then observe this system running in software. The training stresses the link between the parts of the software and physical parts of the machine to ease troubleshooting in the future.

While we will gladly come to your site to troubleshoot software. But we provide this training to go beyond on-call troubleshooting and to get your maintenance team comfortable with the critical parts of your equipment to reduce the need and wait times associated with outside help. By focusing on software, your team can resolve problems much more quickly when downtime happens.

Hardware Training

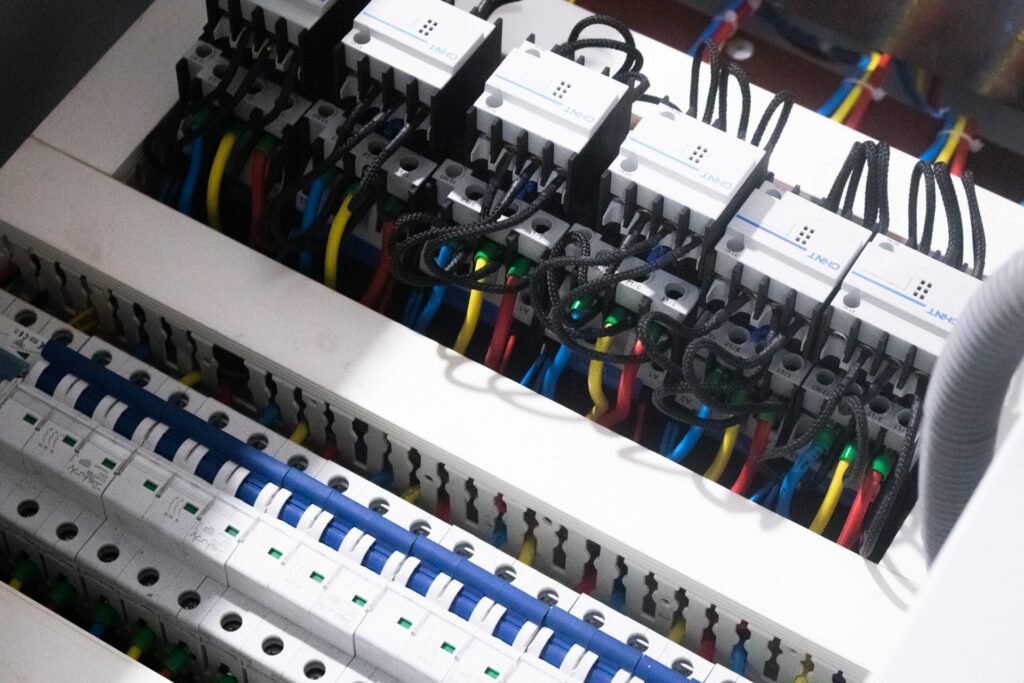

We can review equipment at your site with maintenance and operations staff to identify hardware that your staff may not be completely familiar with. This may include VFDs, servos, robots, vision systems, intelligent sensors and other equipment.

Once we have identified training areas we will produce and present a training plan focused specifically on this hardware and the features of it that are relevant to your equipment installations.

New Equipment Orientation

Bringing new equipment on-line is an exciting time in an industrial facility. Seeing it up and running is a great feeling. But a few months in you’ll have some experience with the equipment and may begin to realize the questions that you needed to ask your vendor when the equipment was being commissioned.

The New Equipment Orientation a combination of the above offerings where we specifically target one piece of equipment, usually something recently installed.

We will observe the equipment operating with your team, gather up any software and functionality related questions and use an analysis of the software to answer these questions. This provides targeted training so you can get the most of your new equipment.

At this time we can also discuss if changes to the software are desired to add or change the machine’s function to better fit your workflow. We are then fully capable of making these changes and validating results.

Contact us to begin discussing any of these services.